Trough screw conveyors from the professional

Trough screw conveyors from the professional

What Is Screw Conveyor

What is a screw conveyor? The screw conveyor is a kind of conveying equipment that is widely applied in the chemical industry, construction industry, and grain industry for transporting powder, granular, and small block materials. Its optimal operating environment temperature is 20~50℃, and the conveying length is generally less than 40m, the longest is not more than 70m, suitable for short-distance materials conveying. Compared with other conveying equipment, it has the advantages of a simple structure, small cross-section size, good sealing performance, safe operation, and low cost. Besides, the screw conveyor can receive materials from one or more points and discharge materials to multiple points, while its conveying capacity is relatively low and the machine parts are easy to wear. In the cement industry, the screw conveyor is indispensable for cement plant equipment. The conveyor produced by AGICO has good rigidity and runs steady, the coaxiality of the helical blade and the helical shaft is high.

Screw Conveyor Design

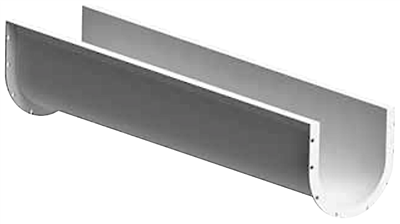

The screw conveyor is mainly composed of head bearing, end bearing, hanger bearing, feeding port, discharge port, screw, trough, trough cover, drive device, etc.

Types Of Screw Conveyor

The screw conveyor can be divided into the ordinary screw conveyor, tubular screw conveyor, and shaftless screw conveyor。

The ordinary screw conveyor is a conveyor that has a screw shaft. It can be further divided into vertical screw conveyor, inclined screw conveyor, and horizontal screw conveyor.

The shaftless screw conveyor has no shaft and equips a liner inside the trough. It has a simple and sealed structure. For many difficult conveying materials, the shaftless screw conveyor is a better solution.

The outside casing of the tubular screw conveyor is made of a seamless steel tube, which has better tightness and rigidity. Although its body is small, the bearing capacity is large, its adaptability is strong, can ensure the uniform delivery of materials.