Replacement Chain and Components

Product Description

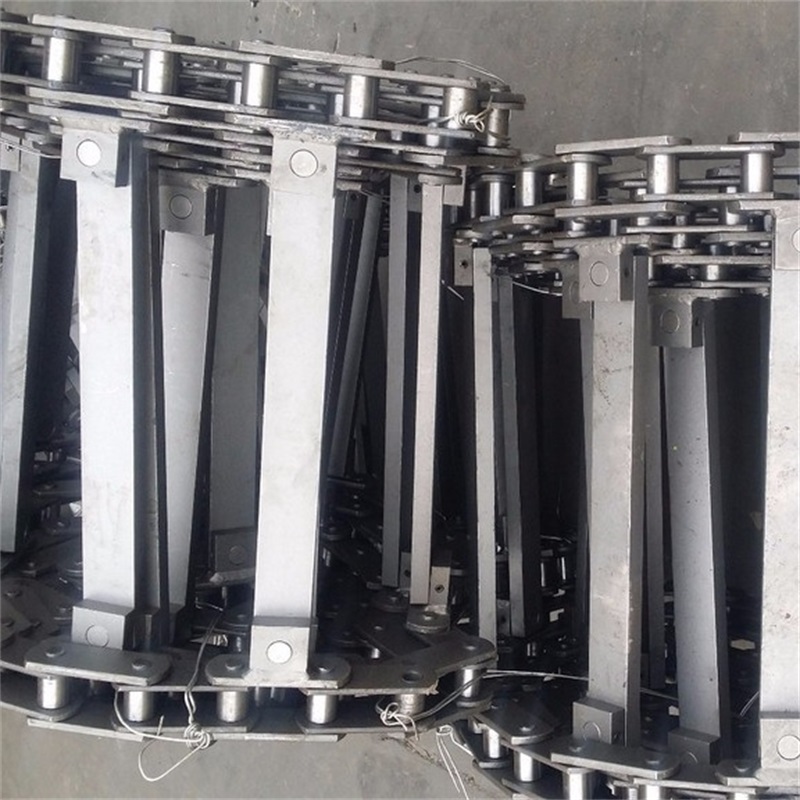

NE series plate chain bucket elevator is an inflow feeding machine. The material flows into the hopper and is lifted to the top by the plate chain, and unloads automatically under the action of material gravity. This series of hoists has many specifications (NE15~NE800, a total of 11 types) and a wide lifting capacity; it has high production capacity and low energy consumption, and can gradually replace other types of hoists. Its main parameters are shown in the table below. The machine adopts a fully enclosed casing with low chain speed and almost no material return phenomenon, so the reactive power loss is small, the noise is low, and the service life is long. The hoist is the most widely used vertical lifting equipment. This machine is suitable for the vertical transportation of medium, large and abrasive materials (such as limestone, cement clinker, gypsum, lump coal), and the material temperature is 250 ° C. the following. NE type plate chain bucket elevator is a new product developed by introducing advanced technology from abroad. The main technical parameters meet the standards of the Ministry of Machinery (JB3926-85). It adopts self-flowing loading and gravity unloading. The chain is high-quality alloy steel high-strength leaf chain, which is wear-resistant and reliable. The driving part adopts hard tooth surface reducer.

ne30 is a more commonly used model in the ne series. It is a single-row plate chain style with a lifting capacity of about 30 tons per hour. It is more common in lifting refractory materials, cement, sand, stones and other materials.

The ne50 bucket elevator chain is a transmission component used in the NE bucket elevator. It adopts plate chain transmission, which is different from the old model TB series plate chain bucket elevator. The naming method of the ne50 bucket elevator chain adopts It is named after the lifting amount instead of the bucket width. For example, the ne50 bucket elevator chain refers to the lifting capacity of 50 tons per hour instead of the bucket width of 50.

The difference between ne15 plate chain elevator chain and ne30 bucket elevator chain: ne15 plate chain elevator chain is suitable for vertical lifting of various materials such as powdery materials to large blocks, and it uses inflow feeding to replace traditional bucket elevators The dig-out type feeding is a replacement product of the traditional bucket elevator. The ne30 bucket elevator chain is a lifting device of plate chain type and gravity induced unloading. It is suitable for vertically conveying powdery, granular, small abrasive or non-abrasive materials, such as raw meal, cement, coal, limestone, dry clay, clinker, etc.

ne plate chain bucket elevator is a new lifting product developed by introducing foreign advanced technology; ne plate chain bucket elevator is used in various industrial countries, due to energy saving and high efficiency, ne plate chain bucket elevator is gradually replacing hl type Equal chain hoist. The ne-type plate chain bucket elevator is inflow feeding, the material flows into the hopper and is lifted to the top by the plate chain, and is unloaded automatically under the action of material gravity. The main technical parameters meet the standards of the Ministry of Machinery (jb3926-85). The ne-type plate chain bucket elevator adopts self-flowing loading and gravity unloading. The chain is a high-quality alloy steel high-strength leaf chain, which is wear-resistant and reliable. The driving part adopts hard tooth surface reducer. The hoist is suitable for vertical conveying of medium, large and abrasive materials (such as limestone, cement clinker, gypsum, lump coal), and the temperature of the materials is controlled below 250°C.