Products

-

Raised Roll Disc Thickness Screen

disc screens are high-performance equipment for screening raw materials, including for automatic separation of organic fractions from household and commercial waste, separation of large foreign objects from the general material flow.

-

Elevator Buckets | Industrial | Agricultural | Manufacturers

Conveyor steel bucket( d bucket)

Materials: Carbon steel, Stainless steel

-

Industrial Roller Conveyor Chains Made in China

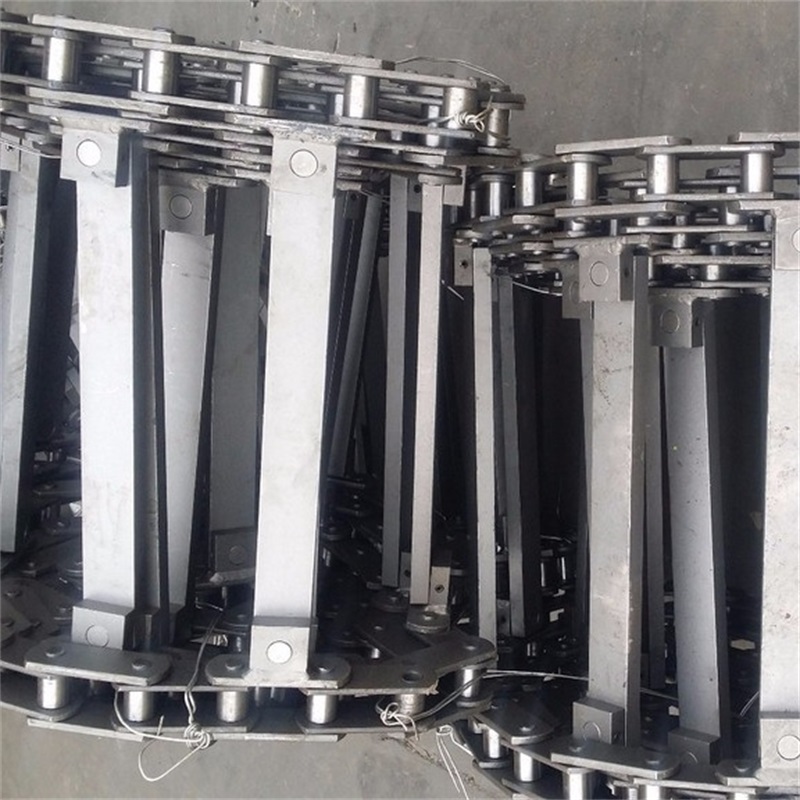

NE series plate chain bucket elevator is an inflow feeding machine. The material flows into the hopper and is lifted to the top by the plate chain, and unloads automatically under the action of material gravity. This series of hoists has many specifications (NE15~NE800, a total of 11 types) and a wide lifting capacity; it has high production capacity and low energy consumption, and can gradually replace other types of hoists. Its main parameters are shown in the table below.

-

Conveyor chain sprockets

NE series plate chain bucket elevator is an inflow feeding machine. The material flows into the hopper and is lifted to the top by the plate chain, and unloads automatically under the action of material gravity. This series of hoists has many specifications (NE15~NE800, a total of 11 types) and a wide lifting capacity; it has high production capacity and low energy consumption, and can gradually replace other types of hoists. Its main parameters are shown in the table below.

-

Top-Quality Conveyor Chain and Sprockets

NE series plate chain bucket elevator is an inflow feeding machine. The material flows into the hopper and is lifted to the top by the plate chain, and unloads automatically under the action of material gravity. This series of hoists has many specifications (NE15~NE800, a total of 11 types) and a wide lifting capacity; it has high production capacity and low energy consumption, and can gradually replace other types of hoists. Its main parameters are shown in the table below.

-

Industrial Conveyor Roller Chains

NE series plate chain bucket elevator is an inflow feeding machine. The material flows into the hopper and is lifted to the top by the plate chain, and unloads automatically under the action of material gravity. This series of hoists has many specifications (NE15~NE800, a total of 11 types) and a wide lifting capacity; it has high production capacity and low energy consumption, and can gradually replace other types of hoists. Its main parameters are shown in the table below.

-

Conveyor Roller Chain

NE series plate chain bucket elevator is an inflow feeding machine. The material flows into the hopper and is lifted to the top by the plate chain, and unloads automatically under the action of material gravity. This series of hoists has many specifications (NE15~NE800, a total of 11 types) and a wide lifting capacity; it has high production capacity and low energy consumption, and can gradually replace other types of hoists. Its main parameters are shown in the table below.

-

General use small size conveyor chain; Product information

NE series plate chain bucket elevator is an inflow feeding machine. The material flows into the hopper and is lifted to the top by the plate chain, and unloads automatically under the action of material gravity. This series of hoists has many specifications (NE15~NE800, a total of 11 types) and a wide lifting capacity; it has high production capacity and low energy consumption, and can gradually replace other types of hoists. Its main parameters are shown in the table below.

-

Conveyor chains and accessories

NE series plate chain bucket elevator is an inflow feeding machine. The material flows into the hopper and is lifted to the top by the plate chain, and unloads automatically under the action of material gravity. This series of hoists has many specifications (NE15~NE800, a total of 11 types) and a wide lifting capacity; it has high production capacity and low energy consumption, and can gradually replace other types of hoists. Its main parameters are shown in the table below.

-

General-use, heavy duty large size conveyor chain

NE series plate chain bucket elevator is an inflow feeding machine. The material flows into the hopper and is lifted to the top by the plate chain, and unloads automatically under the action of material gravity. This series of hoists has many specifications (NE15~NE800, a total of 11 types) and a wide lifting capacity; it has high production capacity and low energy consumption, and can gradually replace other types of hoists. Its main parameters are shown in the table below.

-

Conveyor Chain – Long Lasting Conveyor Chains

NE series plate chain bucket elevator is an inflow feeding machine. The material flows into the hopper and is lifted to the top by the plate chain, and unloads automatically under the action of material gravity. This series of hoists has many specifications (NE15~NE800, a total of 11 types) and a wide lifting capacity; it has high production capacity and low energy consumption, and can gradually replace other types of hoists. Its main parameters are shown in the table below.

-

Conveyor Chain Products

NE series plate chain bucket elevator is an inflow feeding machine. The material flows into the hopper and is lifted to the top by the plate chain, and unloads automatically under the action of material gravity. This series of hoists has many specifications (NE15~NE800, a total of 11 types) and a wide lifting capacity; it has high production capacity and low energy consumption, and can gradually replace other types of hoists. Its main parameters are shown in the table below.