Products

-

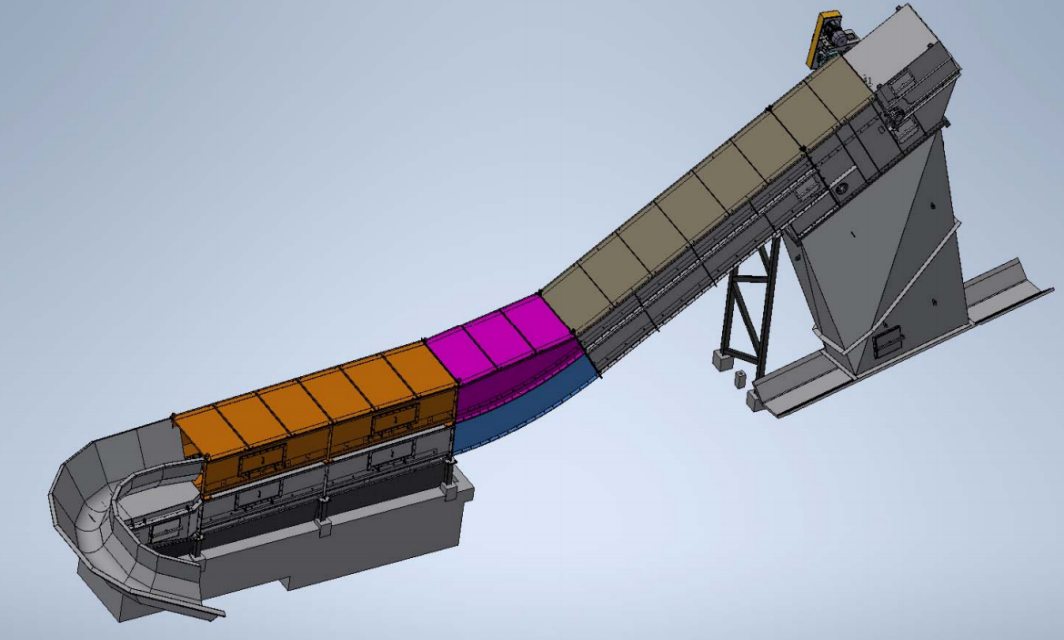

Bottom Ash Handling System

Chain Conveyor, Drag Chain Conveyor, Scraper Conveyor, Trough Chain Conveyor, Buried Scraper Conveyer, En Masse Conveyor for Cement/Coal/Grain/Fertilizer/Soda

Basic Info.

Model NO.MSType:Chain ConveyorStructureChain ConveyorMaterialCarbon Steel/Stainless SteelMaterial FeaturSturdy and DurableCertificationISO9001:2008According to Customer RequirementsProduct DescriptionDescription:Drag Chain Conveyor is a conveying device for continuously conveying powder, granules and small pieces of granular materials in a closed casing by means of a moving scraper chain. Since the scraper chain is buried in the material to be conveyed, it is called a buried scraper conveyor. When transporting horizontally, the material is subjected to the thrust of the scraper chain in the running direction. The material is conveyed forward with the scraper chain to form a continuous overall material flow.

Drag Chain Conveyor is widely used in metallurgy, building materials, power plants, grain, mining, food and other industry.General Technical Parameter:

Drag chain Conveyor Technical Specifications Machine Item MS25 MS32 MS40 MS50 MS63 MS80 Chute Width(mm) 250 315 400 500 630 800 Capacity(t/h) 25/31.5 40/50 80/100 160/200 200/250 315/400 Max Conveying Distance(m) 50 50 50 50 50 50 Scrapper Chain Model 3002T 3002T 3003T 3003T 3003T 3003T Allowable load(kn) 33.4 45 100 100 275 2100 Weight(kg/m) 13.87 15.36 25.34 25.34 47.6 52.32 Operating speed(m/s) 0.16/0.20/0.25/0.32 Product Details:Feature:- The traction chain has high strength and can be used for long distance transportation.

- Processes such as sorting, drying, cooling or assembly can be performed during the transport process.

- Drag Chain Conveyor is simple structure,light weight,small volume and floor space. Easy to produce, install and maintain.

- Flexible layout, horizontal or incline conveying materials can be realized. Continuous operation, multi-point feed and discharge.

- Conveying airtight, dustproof, anti-virus, explosion-proof. Ambient temperatures of -20 to +45 °C.

- Drag Chain Conveyor is widely used in conveying powdery and granular materials, and can realize multi-point feeding and multi-point unloading.

- The Drag Chain Conveyor is reasonable in design, simple in structure, and small in cross-section, which can reduce the installation space.

-

Air-cooled Dry Bottom Ash Handling Technology at Coal Fired Power Plant

The double chain scraper conveyor is a kind of conveying of materials in the form of double chains. It is designed for the situation of large conveying volume. The structure of the buried scraper is simple. It can be arranged in combination, transported in series, can be fed at multiple points, unloaded at multiple points, and the process layout is more flexible. Due to the closed shell, the working conditions can be significantly improved when conveying materials and environmental pollution can be prevented.

-

Bottom Ash Handling System

Chain Conveyor, Drag Chain Conveyor, Scraper Conveyor, Trough Chain Conveyor, Buried Scraper Conveyer, En Masse Conveyor for Cement/Coal/Grain/Fertilizer/Soda

Basic Info.

Model NO.MSType:Chain ConveyorStructureChain ConveyorMaterialCarbon Steel/Stainless SteelMaterial FeaturSturdy and DurableCertificationISO9001:2008According to Customer RequirementsProduct DescriptionDescription:Drag Chain Conveyor is a conveying device for continuously conveying powder, granules and small pieces of granular materials in a closed casing by means of a moving scraper chain. Since the scraper chain is buried in the material to be conveyed, it is called a buried scraper conveyor. When transporting horizontally, the material is subjected to the thrust of the scraper chain in the running direction. The material is conveyed forward with the scraper chain to form a continuous overall material flow.

Drag Chain Conveyor is widely used in metallurgy, building materials, power plants, grain, mining, food and other industry.General Technical Parameter:

Drag chain Conveyor Technical Specifications Machine Item MS25 MS32 MS40 MS50 MS63 MS80 Chute Width(mm) 250 315 400 500 630 800 Capacity(t/h) 25/31.5 40/50 80/100 160/200 200/250 315/400 Max Conveying Distance(m) 50 50 50 50 50 50 Scrapper Chain Model 3002T 3002T 3003T 3003T 3003T 3003T Allowable load(kn) 33.4 45 100 100 275 2100 Weight(kg/m) 13.87 15.36 25.34 25.34 47.6 52.32 Operating speed(m/s) 0.16/0.20/0.25/0.32 Product Details:Feature:- The traction chain has high strength and can be used for long distance transportation.

- Processes such as sorting, drying, cooling or assembly can be performed during the transport process.

- Drag Chain Conveyor is simple structure,light weight,small volume and floor space. Easy to produce, install and maintain.

- Flexible layout, horizontal or incline conveying materials can be realized. Continuous operation, multi-point feed and discharge.

- Conveying airtight, dustproof, anti-virus, explosion-proof. Ambient temperatures of -20 to +45 °C.

- Drag Chain Conveyor is widely used in conveying powdery and granular materials, and can realize multi-point feeding and multi-point unloading.

- The Drag Chain Conveyor is reasonable in design, simple in structure, and small in cross-section, which can reduce the installation space.

-

Air-cooled Dry Bottom Ash Handling Technology at Coal Fired Power Plant

The double chain scraper conveyor is a kind of conveying of materials in the form of double chains. It is designed for the situation of large conveying volume. The structure of the buried scraper is simple. It can be arranged in combination, transported in series, can be fed at multiple points, unloaded at multiple points, and the process layout is more flexible. Due to the closed shell, the working conditions can be significantly improved when conveying materials and environmental pollution can be prevented.

-

Bottom Ash Handling System

Chain Conveyor, Drag Chain Conveyor, Scraper Conveyor, Trough Chain Conveyor, Buried Scraper Conveyer, En Masse Conveyor for Cement/Coal/Grain/Fertilizer/Soda

Basic Info.

Model NO.MSType:Chain ConveyorStructureChain ConveyorMaterialCarbon Steel/Stainless SteelMaterial FeaturSturdy and DurableCertificationISO9001:2008According to Customer RequirementsProduct DescriptionDescription:Drag Chain Conveyor is a conveying device for continuously conveying powder, granules and small pieces of granular materials in a closed casing by means of a moving scraper chain. Since the scraper chain is buried in the material to be conveyed, it is called a buried scraper conveyor. When transporting horizontally, the material is subjected to the thrust of the scraper chain in the running direction. The material is conveyed forward with the scraper chain to form a continuous overall material flow.

Drag Chain Conveyor is widely used in metallurgy, building materials, power plants, grain, mining, food and other industry.General Technical Parameter:

Drag chain Conveyor Technical Specifications Machine Item MS25 MS32 MS40 MS50 MS63 MS80 Chute Width(mm) 250 315 400 500 630 800 Capacity(t/h) 25/31.5 40/50 80/100 160/200 200/250 315/400 Max Conveying Distance(m) 50 50 50 50 50 50 Scrapper Chain Model 3002T 3002T 3003T 3003T 3003T 3003T Allowable load(kn) 33.4 45 100 100 275 2100 Weight(kg/m) 13.87 15.36 25.34 25.34 47.6 52.32 Operating speed(m/s) 0.16/0.20/0.25/0.32 Product Details:Feature:- The traction chain has high strength and can be used for long distance transportation.

- Processes such as sorting, drying, cooling or assembly can be performed during the transport process.

- Drag Chain Conveyor is simple structure,light weight,small volume and floor space. Easy to produce, install and maintain.

- Flexible layout, horizontal or incline conveying materials can be realized. Continuous operation, multi-point feed and discharge.

- Conveying airtight, dustproof, anti-virus, explosion-proof. Ambient temperatures of -20 to +45 °C.

- Drag Chain Conveyor is widely used in conveying powdery and granular materials, and can realize multi-point feeding and multi-point unloading.

- The Drag Chain Conveyor is reasonable in design, simple in structure, and small in cross-section, which can reduce the installation space.

-

bottom ash treatment system

Chain Conveyor, Drag Chain Conveyor, Scraper Conveyor, Trough Chain Conveyor, Buried Scraper Conveyer, En Masse Conveyor for Cement/Coal/Grain/Fertilizer/Soda

Basic Info.

Model NO.MSType:Chain ConveyorStructureChain ConveyorMaterialCarbon Steel/Stainless SteelMaterial FeaturSturdy and DurableCertificationISO9001:2008According to Customer RequirementsProduct DescriptionDescription:Drag Chain Conveyor is a conveying device for continuously conveying powder, granules and small pieces of granular materials in a closed casing by means of a moving scraper chain. Since the scraper chain is buried in the material to be conveyed, it is called a buried scraper conveyor. When transporting horizontally, the material is subjected to the thrust of the scraper chain in the running direction. The material is conveyed forward with the scraper chain to form a continuous overall material flow.

Drag Chain Conveyor is widely used in metallurgy, building materials, power plants, grain, mining, food and other industry.General Technical Parameter:

Drag chain Conveyor Technical Specifications Machine Item MS25 MS32 MS40 MS50 MS63 MS80 Chute Width(mm) 250 315 400 500 630 800 Capacity(t/h) 25/31.5 40/50 80/100 160/200 200/250 315/400 Max Conveying Distance(m) 50 50 50 50 50 50 Scrapper Chain Model 3002T 3002T 3003T 3003T 3003T 3003T Allowable load(kn) 33.4 45 100 100 275 2100 Weight(kg/m) 13.87 15.36 25.34 25.34 47.6 52.32 Operating speed(m/s) 0.16/0.20/0.25/0.32 Product Details:Feature:- The traction chain has high strength and can be used for long distance transportation.

- Processes such as sorting, drying, cooling or assembly can be performed during the transport process.

- Drag Chain Conveyor is simple structure,light weight,small volume and floor space. Easy to produce, install and maintain.

- Flexible layout, horizontal or incline conveying materials can be realized. Continuous operation, multi-point feed and discharge.

- Conveying airtight, dustproof, anti-virus, explosion-proof. Ambient temperatures of -20 to +45 °C.

- Drag Chain Conveyor is widely used in conveying powdery and granular materials, and can realize multi-point feeding and multi-point unloading.

- The Drag Chain Conveyor is reasonable in design, simple in structure, and small in cross-section, which can reduce the installation space.

-

Dry bottom ash discharge + treatment systems

Chain Conveyor, Drag Chain Conveyor, Scraper Conveyor, Trough Chain Conveyor, Buried Scraper Conveyer, En Masse Conveyor for Cement/Coal/Grain/Fertilizer/Soda

Basic Info.

Model NO.MSType:Chain ConveyorStructureChain ConveyorMaterialCarbon Steel/Stainless SteelMaterial FeaturSturdy and DurableCertificationISO9001:2008According to Customer RequirementsProduct DescriptionDescription:Drag Chain Conveyor is a conveying device for continuously conveying powder, granules and small pieces of granular materials in a closed casing by means of a moving scraper chain. Since the scraper chain is buried in the material to be conveyed, it is called a buried scraper conveyor. When transporting horizontally, the material is subjected to the thrust of the scraper chain in the running direction. The material is conveyed forward with the scraper chain to form a continuous overall material flow.

Drag Chain Conveyor is widely used in metallurgy, building materials, power plants, grain, mining, food and other industry.General Technical Parameter:

Drag chain Conveyor Technical Specifications Machine Item MS25 MS32 MS40 MS50 MS63 MS80 Chute Width(mm) 250 315 400 500 630 800 Capacity(t/h) 25/31.5 40/50 80/100 160/200 200/250 315/400 Max Conveying Distance(m) 50 50 50 50 50 50 Scrapper Chain Model 3002T 3002T 3003T 3003T 3003T 3003T Allowable load(kn) 33.4 45 100 100 275 2100 Weight(kg/m) 13.87 15.36 25.34 25.34 47.6 52.32 Operating speed(m/s) 0.16/0.20/0.25/0.32 Product Details:Feature:- The traction chain has high strength and can be used for long distance transportation.

- Processes such as sorting, drying, cooling or assembly can be performed during the transport process.

- Drag Chain Conveyor is simple structure,light weight,small volume and floor space. Easy to produce, install and maintain.

- Flexible layout, horizontal or incline conveying materials can be realized. Continuous operation, multi-point feed and discharge.

- Conveying airtight, dustproof, anti-virus, explosion-proof. Ambient temperatures of -20 to +45 °C.

- Drag Chain Conveyor is widely used in conveying powdery and granular materials, and can realize multi-point feeding and multi-point unloading.

- The Drag Chain Conveyor is reasonable in design, simple in structure, and small in cross-section, which can reduce the installation space.

-

Conveying systems for Waste-to-Energy Incineration

Chain Conveyor, Drag Chain Conveyor, Scraper Conveyor, Trough Chain Conveyor, Buried Scraper Conveyer, En Masse Conveyor for Cement/Coal/Grain/Fertilizer/Soda

Basic Info.

Model NO.MSType:Chain ConveyorStructureChain ConveyorMaterialCarbon Steel/Stainless SteelMaterial FeaturSturdy and DurableCertificationISO9001:2008According to Customer RequirementsProduct DescriptionDescription:Drag Chain Conveyor is a conveying device for continuously conveying powder, granules and small pieces of granular materials in a closed casing by means of a moving scraper chain. Since the scraper chain is buried in the material to be conveyed, it is called a buried scraper conveyor. When transporting horizontally, the material is subjected to the thrust of the scraper chain in the running direction. The material is conveyed forward with the scraper chain to form a continuous overall material flow.

Drag Chain Conveyor is widely used in metallurgy, building materials, power plants, grain, mining, food and other industry.General Technical Parameter:

Drag chain Conveyor Technical Specifications Machine Item MS25 MS32 MS40 MS50 MS63 MS80 Chute Width(mm) 250 315 400 500 630 800 Capacity(t/h) 25/31.5 40/50 80/100 160/200 200/250 315/400 Max Conveying Distance(m) 50 50 50 50 50 50 Scrapper Chain Model 3002T 3002T 3003T 3003T 3003T 3003T Allowable load(kn) 33.4 45 100 100 275 2100 Weight(kg/m) 13.87 15.36 25.34 25.34 47.6 52.32 Operating speed(m/s) 0.16/0.20/0.25/0.32 Product Details:Feature:- The traction chain has high strength and can be used for long distance transportation.

- Processes such as sorting, drying, cooling or assembly can be performed during the transport process.

- Drag Chain Conveyor is simple structure,light weight,small volume and floor space. Easy to produce, install and maintain.

- Flexible layout, horizontal or incline conveying materials can be realized. Continuous operation, multi-point feed and discharge.

- Conveying airtight, dustproof, anti-virus, explosion-proof. Ambient temperatures of -20 to +45 °C.

- Drag Chain Conveyor is widely used in conveying powdery and granular materials, and can realize multi-point feeding and multi-point unloading.

- The Drag Chain Conveyor is reasonable in design, simple in structure, and small in cross-section, which can reduce the installation space.

-

Conveyor for Waste-to-Energy | Modular Power Plant

Chain Conveyor, Drag Chain Conveyor, Scraper Conveyor, Trough Chain Conveyor, Buried Scraper Conveyer, En Masse Conveyor for Cement/Coal/Grain/Fertilizer/Soda

Basic Info.

Model NO.MSType:Chain ConveyorStructureChain ConveyorMaterialCarbon Steel/Stainless SteelMaterial FeaturSturdy and DurableCertificationISO9001:2008According to Customer RequirementsProduct DescriptionDescription:Drag Chain Conveyor is a conveying device for continuously conveying powder, granules and small pieces of granular materials in a closed casing by means of a moving scraper chain. Since the scraper chain is buried in the material to be conveyed, it is called a buried scraper conveyor. When transporting horizontally, the material is subjected to the thrust of the scraper chain in the running direction. The material is conveyed forward with the scraper chain to form a continuous overall material flow.

Drag Chain Conveyor is widely used in metallurgy, building materials, power plants, grain, mining, food and other industry.General Technical Parameter:

Drag chain Conveyor Technical Specifications Machine Item MS25 MS32 MS40 MS50 MS63 MS80 Chute Width(mm) 250 315 400 500 630 800 Capacity(t/h) 25/31.5 40/50 80/100 160/200 200/250 315/400 Max Conveying Distance(m) 50 50 50 50 50 50 Scrapper Chain Model 3002T 3002T 3003T 3003T 3003T 3003T Allowable load(kn) 33.4 45 100 100 275 2100 Weight(kg/m) 13.87 15.36 25.34 25.34 47.6 52.32 Operating speed(m/s) 0.16/0.20/0.25/0.32 Product Details:Feature:- The traction chain has high strength and can be used for long distance transportation.

- Processes such as sorting, drying, cooling or assembly can be performed during the transport process.

- Drag Chain Conveyor is simple structure,light weight,small volume and floor space. Easy to produce, install and maintain.

- Flexible layout, horizontal or incline conveying materials can be realized. Continuous operation, multi-point feed and discharge.

- Conveying airtight, dustproof, anti-virus, explosion-proof. Ambient temperatures of -20 to +45 °C.

- Drag Chain Conveyor is widely used in conveying powdery and granular materials, and can realize multi-point feeding and multi-point unloading.

- The Drag Chain Conveyor is reasonable in design, simple in structure, and small in cross-section, which can reduce the installation space.

-

Conveyor for Modular Waste-to-Energy Plants

Chain Conveyor, Drag Chain Conveyor, Scraper Conveyor, Trough Chain Conveyor, Buried Scraper Conveyer, En Masse Conveyor for Cement/Coal/Grain/Fertilizer/Soda

Basic Info.

Model NO.MSType:Chain ConveyorStructureChain ConveyorMaterialCarbon Steel/Stainless SteelMaterial FeaturSturdy and DurableCertificationISO9001:2008According to Customer RequirementsProduct DescriptionDescription:Drag Chain Conveyor is a conveying device for continuously conveying powder, granules and small pieces of granular materials in a closed casing by means of a moving scraper chain. Since the scraper chain is buried in the material to be conveyed, it is called a buried scraper conveyor. When transporting horizontally, the material is subjected to the thrust of the scraper chain in the running direction. The material is conveyed forward with the scraper chain to form a continuous overall material flow.

Drag Chain Conveyor is widely used in metallurgy, building materials, power plants, grain, mining, food and other industry.General Technical Parameter:

Drag chain Conveyor Technical Specifications Machine Item MS25 MS32 MS40 MS50 MS63 MS80 Chute Width(mm) 250 315 400 500 630 800 Capacity(t/h) 25/31.5 40/50 80/100 160/200 200/250 315/400 Max Conveying Distance(m) 50 50 50 50 50 50 Scrapper Chain Model 3002T 3002T 3003T 3003T 3003T 3003T Allowable load(kn) 33.4 45 100 100 275 2100 Weight(kg/m) 13.87 15.36 25.34 25.34 47.6 52.32 Operating speed(m/s) 0.16/0.20/0.25/0.32 Product Details:Feature:- The traction chain has high strength and can be used for long distance transportation.

- Processes such as sorting, drying, cooling or assembly can be performed during the transport process.

- Drag Chain Conveyor is simple structure,light weight,small volume and floor space. Easy to produce, install and maintain.

- Flexible layout, horizontal or incline conveying materials can be realized. Continuous operation, multi-point feed and discharge.

- Conveying airtight, dustproof, anti-virus, explosion-proof. Ambient temperatures of -20 to +45 °C.

- Drag Chain Conveyor is widely used in conveying powdery and granular materials, and can realize multi-point feeding and multi-point unloading.

- The Drag Chain Conveyor is reasonable in design, simple in structure, and small in cross-section, which can reduce the installation space.

-

Chain Conveyor for waste-to-energy incinerators

Chain Conveyor, Drag Chain Conveyor, Scraper Conveyor, Trough Chain Conveyor, Buried Scraper Conveyer, En Masse Conveyor for Cement/Coal/Grain/Fertilizer/Soda

Basic Info.

Model NO.MSType:Chain ConveyorStructureChain ConveyorMaterialCarbon Steel/Stainless SteelMaterial FeaturSturdy and DurableCertificationISO9001:2008According to Customer RequirementsProduct DescriptionDescription:Drag Chain Conveyor is a conveying device for continuously conveying powder, granules and small pieces of granular materials in a closed casing by means of a moving scraper chain. Since the scraper chain is buried in the material to be conveyed, it is called a buried scraper conveyor. When transporting horizontally, the material is subjected to the thrust of the scraper chain in the running direction. The material is conveyed forward with the scraper chain to form a continuous overall material flow.

Drag Chain Conveyor is widely used in metallurgy, building materials, power plants, grain, mining, food and other industry.General Technical Parameter:

Drag chain Conveyor Technical Specifications Machine Item MS25 MS32 MS40 MS50 MS63 MS80 Chute Width(mm) 250 315 400 500 630 800 Capacity(t/h) 25/31.5 40/50 80/100 160/200 200/250 315/400 Max Conveying Distance(m) 50 50 50 50 50 50 Scrapper Chain Model 3002T 3002T 3003T 3003T 3003T 3003T Allowable load(kn) 33.4 45 100 100 275 2100 Weight(kg/m) 13.87 15.36 25.34 25.34 47.6 52.32 Operating speed(m/s) 0.16/0.20/0.25/0.32 Product Details:Feature:- The traction chain has high strength and can be used for long distance transportation.

- Processes such as sorting, drying, cooling or assembly can be performed during the transport process.

- Drag Chain Conveyor is simple structure,light weight,small volume and floor space. Easy to produce, install and maintain.

- Flexible layout, horizontal or incline conveying materials can be realized. Continuous operation, multi-point feed and discharge.

- Conveying airtight, dustproof, anti-virus, explosion-proof. Ambient temperatures of -20 to +45 °C.

- Drag Chain Conveyor is widely used in conveying powdery and granular materials, and can realize multi-point feeding and multi-point unloading.

- The Drag Chain Conveyor is reasonable in design, simple in structure, and small in cross-section, which can reduce the installation space.

-

Chain Conveyor for waste-to-power incinerators plant

Chain Conveyor, Drag Chain Conveyor, Scraper Conveyor, Trough Chain Conveyor, Buried Scraper Conveyer, En Masse Conveyor for Cement/Coal/Grain/Fertilizer/Soda

Basic Info.

Model NO.MSType:Chain ConveyorStructureChain ConveyorMaterialCarbon Steel/Stainless SteelMaterial FeaturSturdy and DurableCertificationISO9001:2008According to Customer RequirementsProduct DescriptionDescription:Drag Chain Conveyor is a conveying device for continuously conveying powder, granules and small pieces of granular materials in a closed casing by means of a moving scraper chain. Since the scraper chain is buried in the material to be conveyed, it is called a buried scraper conveyor. When transporting horizontally, the material is subjected to the thrust of the scraper chain in the running direction. The material is conveyed forward with the scraper chain to form a continuous overall material flow.

Drag Chain Conveyor is widely used in metallurgy, building materials, power plants, grain, mining, food and other industry.General Technical Parameter:

Drag chain Conveyor Technical Specifications Machine Item MS25 MS32 MS40 MS50 MS63 MS80 Chute Width(mm) 250 315 400 500 630 800 Capacity(t/h) 25/31.5 40/50 80/100 160/200 200/250 315/400 Max Conveying Distance(m) 50 50 50 50 50 50 Scrapper Chain Model 3002T 3002T 3003T 3003T 3003T 3003T Allowable load(kn) 33.4 45 100 100 275 2100 Weight(kg/m) 13.87 15.36 25.34 25.34 47.6 52.32 Operating speed(m/s) 0.16/0.20/0.25/0.32 Product Details:Feature:- The traction chain has high strength and can be used for long distance transportation.

- Processes such as sorting, drying, cooling or assembly can be performed during the transport process.

- Drag Chain Conveyor is simple structure,light weight,small volume and floor space. Easy to produce, install and maintain.

- Flexible layout, horizontal or incline conveying materials can be realized. Continuous operation, multi-point feed and discharge.

- Conveying airtight, dustproof, anti-virus, explosion-proof. Ambient temperatures of -20 to +45 °C.

- Drag Chain Conveyor is widely used in conveying powdery and granular materials, and can realize multi-point feeding and multi-point unloading.

- The Drag Chain Conveyor is reasonable in design, simple in structure, and small in cross-section, which can reduce the installation space.