Products

-

Cooling Screw Conveyor

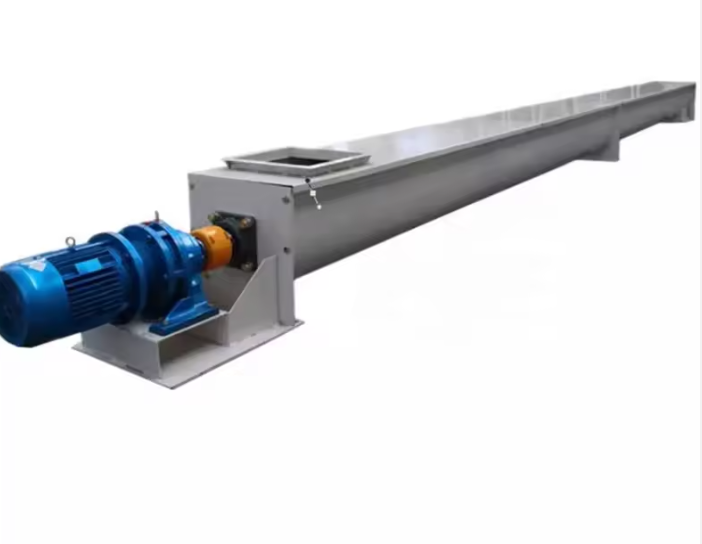

COOLING SCREW CONVEYORCooling screws from Jiangsu Bootec Environment Engineering Co., Ltd. are designed as pipe or trough screws. They are used in grate firing as well as downstream of fluidized bed and rotary kilns to cool down bulk materials with temperatures of up to 1000 °C for further transport.

The bulk material is conveyed by rotation of the screw shaft. During conveying, cooling water flows through and cools the trough shell and/or the screw shaft.

As a special screw heat exchanger, it is particularly well suited for hot ash cooling in sewage sludge applications.

-

Screw Conveyor | Cooling Screw Conveyor

COOLING SCREW CONVEYORCooling screws from Jiangsu Bootec Environment Engineering Co., Ltd. are designed as pipe or trough screws. They are used in grate firing as well as downstream of fluidized bed and rotary kilns to cool down bulk materials with temperatures of up to 1000 °C for further transport.

The bulk material is conveyed by rotation of the screw shaft. During conveying, cooling water flows through and cools the trough shell and/or the screw shaft.

As a special screw heat exchanger, it is particularly well suited for hot ash cooling in sewage sludge applications.

-

Screw Conveyor Corporation: Bulk Handling Equipment

COOLING SCREW CONVEYORCooling screws from Jiangsu Bootec Environment Engineering Co., Ltd. are designed as pipe or trough screws. They are used in grate firing as well as downstream of fluidized bed and rotary kilns to cool down bulk materials with temperatures of up to 1000 °C for further transport.

The bulk material is conveyed by rotation of the screw shaft. During conveying, cooling water flows through and cools the trough shell and/or the screw shaft.

As a special screw heat exchanger, it is particularly well suited for hot ash cooling in sewage sludge applications.

-

Industrial Screw Conveyor – Conveying Equipment

COOLING SCREW CONVEYORCooling screws from Jiangsu Bootec Environment Engineering Co., Ltd. are designed as pipe or trough screws. They are used in grate firing as well as downstream of fluidized bed and rotary kilns to cool down bulk materials with temperatures of up to 1000 °C for further transport.

The bulk material is conveyed by rotation of the screw shaft. During conveying, cooling water flows through and cools the trough shell and/or the screw shaft.

As a special screw heat exchanger, it is particularly well suited for hot ash cooling in sewage sludge applications.

-

Industries Screw Conveyor Bulk Material Handling

COOLING SCREW CONVEYORCooling screws from Jiangsu Bootec Environment Engineering Co., Ltd. are designed as pipe or trough screws. They are used in grate firing as well as downstream of fluidized bed and rotary kilns to cool down bulk materials with temperatures of up to 1000 °C for further transport.

The bulk material is conveyed by rotation of the screw shaft. During conveying, cooling water flows through and cools the trough shell and/or the screw shaft.

As a special screw heat exchanger, it is particularly well suited for hot ash cooling in sewage sludge applications.

-

Industries Screw Conveyor Bulk Material Handling

COOLING SCREW CONVEYORCooling screws from Jiangsu Bootec Environment Engineering Co., Ltd. are designed as pipe or trough screws. They are used in grate firing as well as downstream of fluidized bed and rotary kilns to cool down bulk materials with temperatures of up to 1000 °C for further transport.

The bulk material is conveyed by rotation of the screw shaft. During conveying, cooling water flows through and cools the trough shell and/or the screw shaft.

As a special screw heat exchanger, it is particularly well suited for hot ash cooling in sewage sludge applications.

-

Screw Conveyor Manufacturers | Screw Conveyor Suppliers

COOLING SCREW CONVEYORCooling screws from Jiangsu Bootec Environment Engineering Co., Ltd. are designed as pipe or trough screws. They are used in grate firing as well as downstream of fluidized bed and rotary kilns to cool down bulk materials with temperatures of up to 1000 °C for further transport.

The bulk material is conveyed by rotation of the screw shaft. During conveying, cooling water flows through and cools the trough shell and/or the screw shaft.

As a special screw heat exchanger, it is particularly well suited for hot ash cooling in sewage sludge applications.

-

Industrial Screw Conveyor

COOLING SCREW CONVEYORCooling screws from Jiangsu Bootec Environment Engineering Co., Ltd. are designed as pipe or trough screws. They are used in grate firing as well as downstream of fluidized bed and rotary kilns to cool down bulk materials with temperatures of up to 1000 °C for further transport.

The bulk material is conveyed by rotation of the screw shaft. During conveying, cooling water flows through and cools the trough shell and/or the screw shaft.

As a special screw heat exchanger, it is particularly well suited for hot ash cooling in sewage sludge applications.

-

Bucket Elevator Components

elevator bucket for any product and any application.

- Steel & stainless steel elevator buckets (pressed / seamless or fabricated)

- Plastic / non-metallic elevator buckets (nylon, HDP or polyurethane)

- Elevator buckets for agricultural applications (e.g. grain, feed, seeds, sugar)

- Elevator buckets for industrial applications (e.g. cement, lime, aggregates, coal, fertilizer)

-

Bucket Elevator Components

Conveyor steel bucket( d bucket)

Materials: Carbon steel, Stainless steel

-

Agricultural Buckets CC Steel

Conveyor steel bucket( d bucket)

Materials: Carbon steel, Stainless steel

-

Welded Customized Elevator Steel Bucket

Conveyor steel bucket( d bucket)

Materials: Carbon steel, Stainless steel