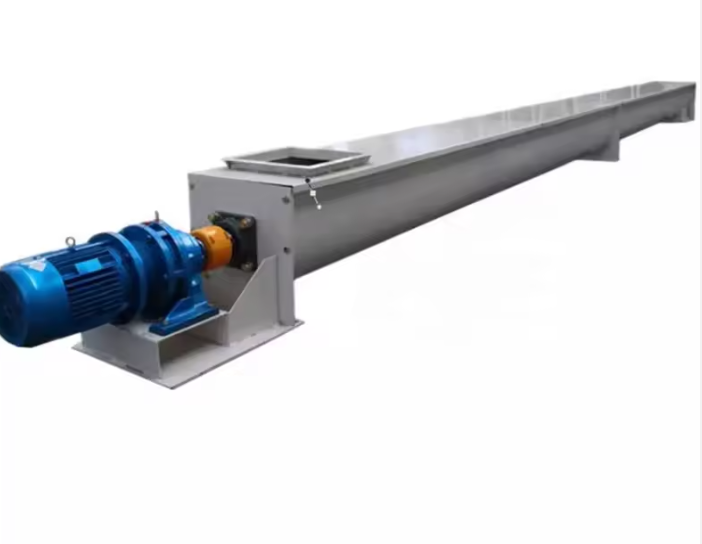

LIVE BOTTOM SCREW CONVEYOR

A live bottom screw conveyor is a type of conveyor system used primarily for moving bulk materials, especially in applications where a consistent and controlled flow of material is needed. Unlike traditional screw conveyors, which rely solely on gravity to move materials, a live bottom screw conveyor features an additional component that helps keep materials flowing smoothly.

Here are some key features and benefits of a live bottom screw conveyor:

1. **Continuous Flow**: The “live bottom” refers to a rotating screw mechanism at the base of the conveyor that ensures a continuous flow of material, even when the material is sticky or prone to clumping.

2. **Controlled Discharge**: The live bottom helps in regulating the discharge of materials from bins or hoppers, preventing issues such as bridging or clogging.

3. **Versatility**: It can handle a variety of materials, including those with high moisture content or those that are prone to caking.

4. **Reduced Wear and Tear**: The live bottom mechanism can help reduce the wear and tear on the rest of the conveyor system by ensuring a consistent flow of material and preventing blockages.

5. **Efficient Operation**: It helps in maintaining an even flow rate, which can be crucial for processes that require precise material handling.

6. **Maintenance**: While they are designed to be robust and durable, live bottom screw conveyors can require regular maintenance to ensure optimal performance.

7. **Applications**: They are commonly used in industries such as agriculture, mining, and manufacturing, particularly where materials need to be transferred from bins or hoppers to other processing equipment.

If you need specific information about the design, installation, or maintenance of a live bottom screw conveyor, or if you have a particular application in mind, feel free to ask!