High-Temperature Screw Conveyors

High-Temperature Screw Conveyors Description

High-Temperature Screw Conveyors TECHNICAL SPECS

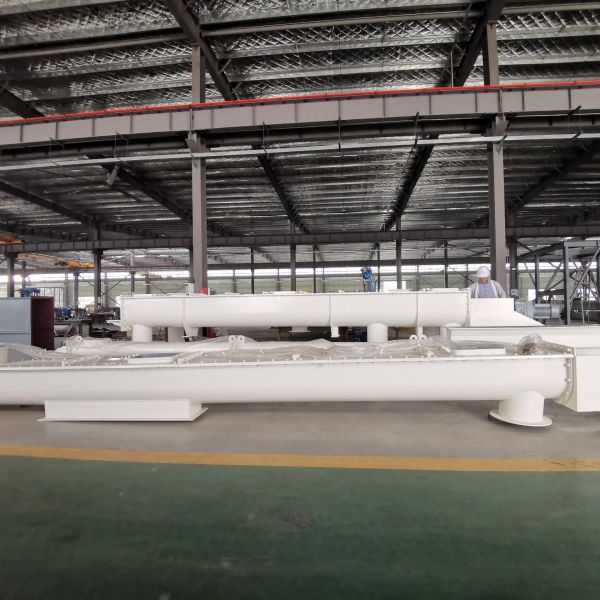

Extra heavy-duty High-Temperature Trough Screw Conveyors are designed for high temperature applications. For this reason, intermediate bearings are absent. High-Temperature are manufactured from carbon or stainless steel with appropriate surface treatment. They are made up of a U-shape trough equipped with at least one outlet spout, an end plate at each trough end, helicoid screw flighting welded on a center pipe with flanged coupling at each end, two end bearing assemblies complete with offset shaft seal, and a bolted trough cover usually equipped with at least one inlet spout. Furthermore, High-Temperature Screw Conveyors are equipped with a gear motor that suits the application.

High-Temperature Screw Conveyors Function

Designed for extra heavy-duty applications, High-Temperature Screw Conveyors satisfy the requirements of conveying or feeding regenerated sand in foundries, coal power stations, or drying plants.

High-Temperature Screw Conveyors Features

Extra heavy-duty fabrication

Wire welding

XUC-type shaft seals with fiberglass seals

Bolted trough covers

Fiberglass gaskets

Flanged shaft couplings

Extra heavy-duty helicoid flights

Insulation spacer (HT)High quality shaft seals with split packing glands (HT)

High-Temperature Screw Conveyors Benefits

Application-specific design features

Robust and durable

Reliable in operation

High-Temperature Screw Conveyors Options

Tapered inlet spouts

Shoe inlets

Square or rectangular inlets

Trough flange brackets for hopper connection

Semi-elastic couplings or chain power transmissions

High-Temperature Screw Conveyors SOLUTIONS

Solutions by Industry

HEAVY INDUSTRIES

Foundries, Iron and Steel Mills, Coking Plants

Power Plants (Fly-Ash Handling)

Solutions by Technology

Bulk Solids Conveying

1.all-round 360 production line cutting group stop workflow, enabling automatic tube feeding, automatic feed, automatic cutting, automatic transmission operation.

2.Using KASRY Nesting programming system as a major programming tool, the software programming platform AUTOCAD basic, simple, graphical and intuitive, feature-rich, it can greatly improve operational efficiency.

3.High-end three-dimensional flexible robotic cutting applications, to achieve bevel cutting function, the pipe and the torch using the servo positioning function .

Bulk Solids Conveying

Can cut carbon steel, stainless steel, copper, aluminum and other pipes and profiles, such as: the tube, pipe, oval pipe, rectangular pipe, H-beam, I-beam, angle, channel, etc. The device is widely used in various kind of pipes profile processing field, shipbuilding industry, network structure, steel, marine engineering, oil pipelines and other industries.

|

LS300-A |

LS300-B |

|

|

Screw Diameter(mm) |

300 |

300 |

|

Screw Pitch(mm) |

300 |

300 |

|

Rotational speed(rpm) |

41 |

41 |

|

Capacity(m³/h) |

30 |

30 |

|

Power (KW) |

4 |

5.5 |

|

Max Distance (m) |

≤5 |

5≤8 |

|

LS400-A |

LS400-B |

|

|

Screw Diameter(mm) |

400 |

400 |

|

Screw Pitch(mm) |

350 |

350 |

|

Rotational speed(rpm) |

33 |

33 |

|

Capacity(m³/h) |

50 |

50 |

|

Power (KW) |

4 |

5.5 |

|

Max Distance (m) |

≤5 |

5≤8 |