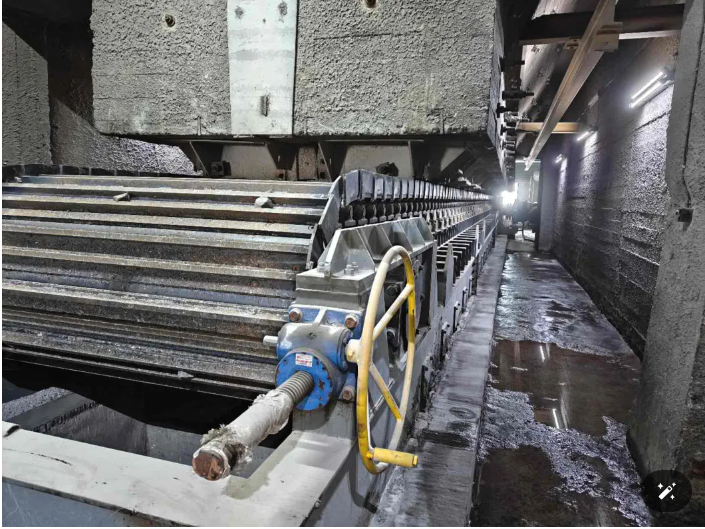

Heavy Apron Feeder for Cement Plant Mining Production Line

Heavy Duty Apron Feeder,is widely used in mining,metallurgy,building materials,coal and other industrial area.It is suitable for short distance transportation for larger piece of material,usually for large concentrator as a continuous,uniform and adjustable storage warehouse to primary crushing equipment.The feeding material can also be used to a short distance conveying,especially when the apron feeder installation at the bottom of the hopper,the pressure of the material directly grained materials.It can complete the heavy work in the bad environment,to the material granularity,the composition change,the temperature,the viscosity,the frost,the rain snow influence or the frozen material all has the relatively big adaptability.General horizontal installation,or tilt installation,the maximum inclination is 25°.

|

Model

|

width(mm)

|

Length(mm)

|

Speed(m/s)

|

Feed Size(mm)

|

Capacity(t/h)

|

|

WBL100-6

|

1000

|

6000

|

0.01-0.1

|

≤ 500

|

80-160

|

|

WBL100-12

|

1000

|

12000

|

0.05-0.1

|

≤ 500

|

60-130

|

|

WBL120-4

|

1200

|

4000

|

0.014-0.08

|

≤ 600

|

45-150

|

|

WBL120-6

|

1200

|

6000

|

0.01-0.1

|

≤ 600

|

80-160

|

|

WBL120-11

|

1200

|

11000

|

0.01-0.1

|

≤ 600

|

50-100

|

|

WBL120-19

|

1200

|

19000

|

0.014-0.09

|

≤ 600

|

45-150

|

|

WBL125-6

|

1250

|

6000

|

0.014-0.08

|

≤ 700

|

45-150

|

|

WBL125-12

|

1250

|

12000

|

0.014-0.08

|

≤ 700

|

45-150

|

|

WBL140-8

|

1400

|

8000

|

0.017-0.17

|

≤ 900

|

100-200

|

|

WBL140-16

|

1400

|

16000

|

0.006-0.06

|

≤ 900

|

20-200

|

|

WBL150-5

|

1500

|

5000

|

0.014-0.08

|

≤ 700

|

85-288

|

|

WBL150-15

|

1500

|

15000

|

0.006-0.06

|

≤ 700

|

20-200

|

|

WBL150-10.5

|

1500

|

10500

|

0.006-0.06

|

≤ 700

|

20-200

|

|

WBL160-6

|

1600

|

6000

|

0.017-0.17

|

≤ 800

|

61-610

|

|

WBL160-9

|

1600

|

9000

|

0.076

|

≤ 800

|

180

|

|

WBL180-8

|

1800

|

8000

|

0.022-0.046

|

≤ 800

|

100-1000

|

|

WBL180-12

|

1800

|

12000

|

0.05

|

≤ 800

|

360

|

|

WBL220-10

|

2200

|

10000

|

0.018-0.055

|

≤ 1500

|

220-680

|

|

WBL240-10

|

2400

|

10000

|

0.018-0.055

|

≤ 1500

|

220-680

|