Flat Belt Conveyor Systems

WHAT IS A BELT CONVEYOR SYSTEM?

Belt Conveyor systems are the most versatile and simplest material handling systems. They work with two or more pulleys driving an endless loop belt. The loop then moves a product from Point A to Point B on the belt. We use belts made from fabric or rubber. Belt conveyors are commonly used in both manufacturing and distribution facilities.

Ultimation designs and builds systems from 5′ long to 102′ long and in widths from 6″ wide belts up to 72″ wide. They are great for transporting regular and irregular shaped objects. Typical items transported on these conveyors include totes, packaged goods and bulk boxes. Due to their simplicity in design and construction, motorized belt conveyors are easily installed. Ultimation can guide you through the selection process of the models available. Heavy duty styles are available as well as lighter duty models. The variations are endless, but most are quite simple.

If you’re ready to buy, we have links to some models right here on this page. Other quick-ship models are listed in our online store. We’ve implemented thousands of systems, and there are hundreds of combinations available.

BELT CONVEYORS FOR INDUSTRIAL AND WAREHOUSE APPLICATIONS

A belt conveyor system can be implemented with a very economical cost per foot of the conveyor for many warehouse and industrial applications. Because it includes just one motor and a simple belt system they are quite simple. Hence they’re often one of the first productivity improvement purchases that a growing company will make. Although there are many belt conveyor types, the simplest style is known as a slider bed style. When linked together with sensors and other automation equipment a conveyor belt system can greatly enhance productivity.

The weakness for them though is that generally they are only used for transport applications. This means that the belt conveyor equipment just moves the product from point A to point B. This may be sufficient, but a belt conveyor cannot typically buffer or accumulate the parts. Nor are they typically used as a working surface for production team members. As one of the leading online belt conveyor manufacturers, Ultimation can guide you through the pros and cons of the different types of belt conveyors. We’ll also help you compare if another different type of conveyor would be a better choice.

WHAT ARE THE TYPES OF CONVEYOR BELT SYSTEMS?

- Slider Bed Belt Conveyor

- Roller Bed

- Incline Belt – Slider

- Incline Belt – Roller

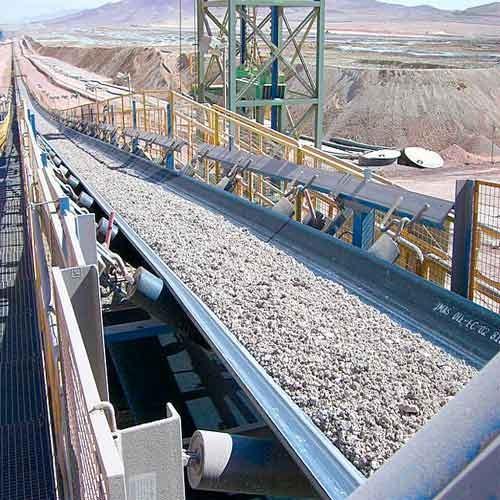

- Troughed Belt Conveyor

- Trough Drum conveyor belt