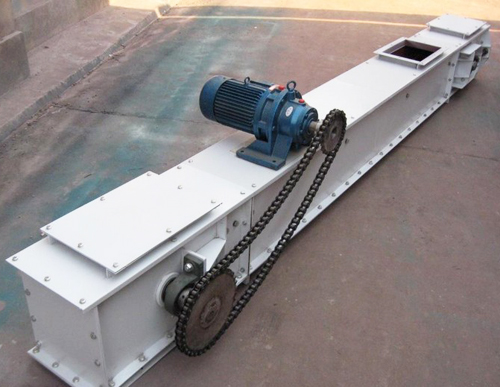

Double Chain Scraper Conveyor

Advantages

1. Solid structure. It can withstand external forces such as impact, impact, smashing and pressure of coal, gangue or other materials.

2. It can adapt to the needs of uneven and bending movement of the floor of the coal mining face, and can withstand vertical or horizontal bending.

3. The body is short and easy to install.

4. It can also be used as the track for the shearer to run.

5. It can run in reverse, which is convenient for dealing with bottom chain accidents.

6. It can be used as the fulcrum of the front section of the hydraulic support.

7. The structure is simple, and the material can be fed or unloaded at any point along the conveying length.

8. the casing is airtight, which can prevent the dust from flying and polluting the environment when conveying materials.

9. When the tail is not equipped with a casing and the scraper is inserted into the material pile, it can take materials and convey them by itself.

Application

Application industry: chemical industry, building materials, metallurgy, electric power, food, sewage, light industry and transportation and other departments

Applicable materials: tailings: iron tailings, gold tailings, copper tailings, vanadium tailings, lead-zinc tailings, graphite tailings, boiler ash, cement clinker, slag, coke, sludge, slag, Coke, gravel, washed sand: quartz sand, zircon sand, glass sand, construction sand, foundry sand, building material sand, potassium feldspar dehydration, tailing coal dehydration: coal slime, coal gangue, sewage treatment: urban sewage, industrial sewage , Solid-liquid separation of river sludge, sewage treatment plants, powder, block, granule, coal, coke, lime, gold placer, powdery, granular, small abrasive or non-abrasive materials, etc.

|

Model |

BG500S |

|

Chute Width (mm) |

500 |

|

Chute Depth(mm) |

500 |

|

Capacity (m3/h) |

30m3/h |

|

Chain Speed (m/s) |

0.12 |

|

Chain Pitch(mm) |

(P1/P2) P=142mm/200mm |

|

Conveyor Length (m) |

5.9<L≤40 |

|

Scraper size(mm) |

142×470×50mm |

|

Transport Material Thickness (mm) |

150mm |

|

Installation Angle (degree) |

≤15° |

|

Motor Power Kw |

7.5 |

|

Drive Installation Type |

Back Mounted (Left/Right) |

|

Transmission Type |

Chain Drive |

|

Ideal Granularity (mm) |

<10 |

|

Maximum Humidity (%) |

≤5% |

|

Maximum Temperature(˚C) |

≤150˚C |

|

Model |

BG640S |

|

Chute Width (mm) |

640 |

|

Chute Depth(mm) |

500 |

|

Capacity (m3/h) |

50m3/h |

|

Chain Speed (m/s) |

0.12 |

|

Chain Pitch(mm) |

(P1/P2) P=142mm/200mm |

|

Conveyor Length (m) |

3.39<L≤30 30≤x≤40 |

|

Scraper size(mm) |

142×600×50mm |

|

Transport Material Thickness (mm) |

200mm |

|

Installation Angle (degree) |

≤15° |

|

Motor Power Kw |

7.5 |

|

Drive Installation Type |

Back Mounted (Left/Right) |

|

Transmission Type |

Chain Drive |

|

Ideal Granularity (mm) |

<10 |

|

Maximum Humidity (%) |

≤5% |

|

Maximum Temperature(˚C) |

≤150˚C |