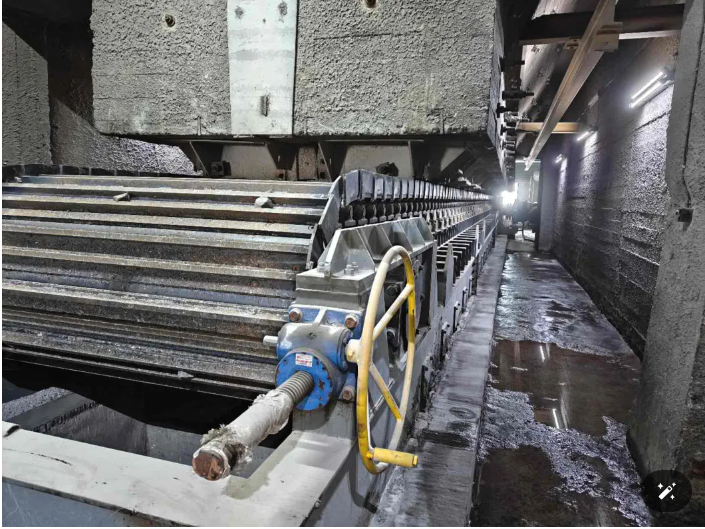

Apron feeder

Apron feeder is the machine for continuous conveying material to crusher, conveyor or other working machine along with horizontal or inclined direction, which is suitable for bulk & block material conveying in large-scale or medium scale cement production line. It can be used in the environment with high temperature and high humidity; especially it can be used to convey material with large block, high temperature in the open air or wet environment.

Apron feeder can be divided into small type apron feeder, medium type apron feeder and heavy type apron feeder, at present; it is mainly used in cement plant to feed material for 1st class limestone raw mineral crusher, meanwhile it could be used for metallurgical, chemical, electrical industry.

Features:

1.Standard heavy-duty ribbed pans prevent excessive deflection under high-impact loading & severely abrasive working conditions.

2. Cast segmental track chain bolted to heavy steel hubs keyed to oversized front drive shaft.

3. Standard crawler-type under carriage parts have a long service life.

4. Rugged steel support frame with impact rails to limit pans deflection, thus eliminating permanent bending of the pans.

5. The heavy-duty design delivers high availability, ease of operation, low maintenance and operational costs and greater profits.

1. The apron feeder is widely used for conveying metal, limestone, gold ore and construction waste, gypsum etc,.

2. It can bear big pressure under large silo or loader.

3. The speed can be adjusted by frequency conversion control cabinet.

4.Including the feed trough, to prevent the material leakage.

5. Thickness of plate is from 8mm to 20mm.

6. Can be customized.

Previous:

Heavy Duty Apron Feeder for Crushing Plant and Cement Plant

Next:

Apron Feeder for Conveying Materials