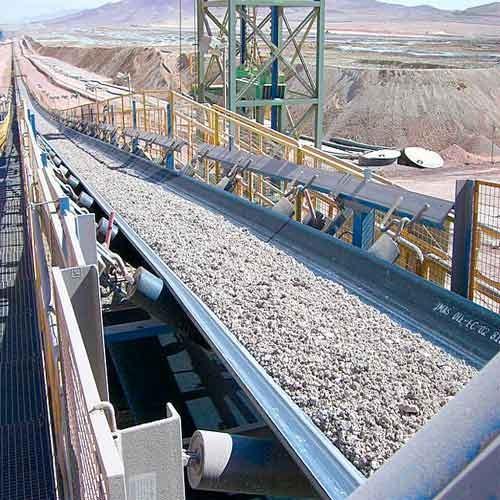

CONVEYOR FOR SLAG PROCESSING PLANTS

BOOTEC’s mechanical bottom ash processing plants consists of several process steps in which the bottom ash is sorted and recycled. By using separation units such as screens, ferrous and non-ferrous separators and air separators, ferrous and non-ferrous metals, ash and slag are separated from each other. We use belt and vibration conveyors for product transportation and distribution. Lumps and chunks are crushed by grinding tools and then divided into different grain sizes by screens and separators. The separated metals can be reused in the metallurgical industry, while ashes and slag can be recycled in road construction or civil engineering, for example. Our solutions are characterized by low energy consumption, high system availability, durability and high added value.

TECHNOLOGIES FOR SLAG PROCESSING PLANTS

- Belt conveyors

- Screens

- Disc Screens

- Magnetic separators

- Non-ferrous metal separators

- Vibratory feeders

- Hoppers

- Electric control system

- Steel structures, platforms, accesses

- Components

- Special solutions

Write your message here and send it to us