CONVEYOR FOR SLAG AND ASH CONVEYING

BOOTEC is your expert for high-performance conveying technology in the bulk solids industry and specializes in thermal waste treatment. Thanks to our many years of experience, we offer tailor-made solutions for the sustainable treatment and recycling of residual materials such as ash and slag.

Our sturdy and reliable ash removal systems are perfectly tailored to the individual requirements of waste-to-energy plants (WtE) and refuse-derived fuel (RDF) power plants. We use different conveyor systems to allow efficient handling and safe conveying of the residual materials.

We attach great importance to the availability and durability of our components. With over 16 years of experience in ash and slag conveying, our customers benefit from our in-depth knowledge and extensive application experience.

Find out more about our innovative conveying technologies and benefit from our sustainable and efficient solutions for the treatment of residual materials.

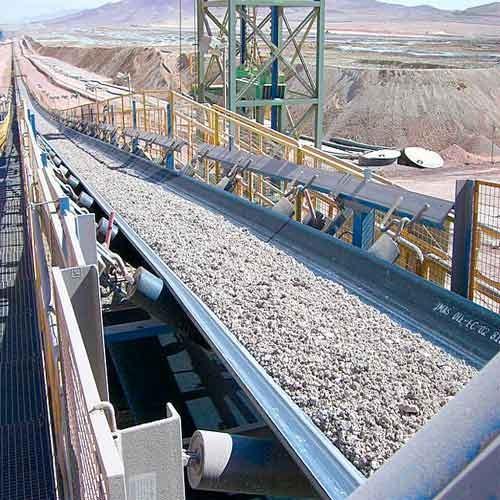

BOOTEC specializes in the manufacture of high-quality conveyor technology for waste incineration. Our ash removal systems are designed to reliably transport ash and slag out of the incineration process. We use various mechanical conveying systems, depending on the temperature and quantity of ash produced. The resulting fly ash can be conveyed to the ash silo using our pneumatic conveying systems. For the efficient disposal of slag after the incineration process, we rely on slag and ash conveyors that can convey dry or wet, depending on requirements. Our conveyor systems are designed, manufactured and installed by our competent engineers and specialists and meet the highest standards of availability, robust design and durability – all aspects of sustainable conveyor technology. In addition, process engineering components are used to screen and sort the bottom ash on its way to downstream bottom ash processing plants.

TECHNOLOGIES FOR SLAG AND ASH CONVEYING

- Dry ash conveyor

- Slag conveyors and ash conveyors

- Apron wet slag conveyor

- Scraper wet slag conveyor

- Slag pusher

- Belt conveyors

- Trough chain conveyors

- Screw conveyors

- Cooling screw conveyors

- Pan conveyors

- Residues transfer stations

- Silo screw reclaimers

- Pneumatic conveying systems

- Feed hopper and hopper cars

- Silos

- Rotary feeders

- Components

- Special solutions