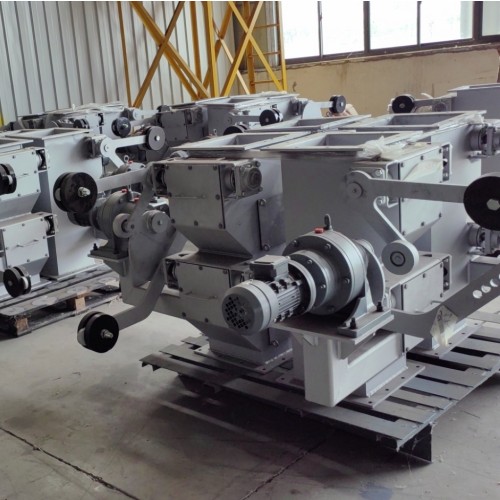

C-Series Double Flap Gate Airlock Valves

Electric double flap valve The double flap valve is an ideal ash discharge valve in metallurgical, nonferrous metal and environmental protection dust removal equipment. Double-deck heavy hammer dump valve is a chain conveyor driven by the transmission rod through the crank, cam and connecting rod drive up and down drive shaft rotation, interactive open, through the equipped lever system or stretching springs, ensure that the feeder valve reliable reset, double-deck electric air-lock dump

flap valve

The flap valve is used as the ash hopper unloading device of various types of removal equipment and the feeding and unloading device of various mills, dryers, silos and other equipment to prevent wild wind from blowing in. It is used with heavy hammers, electric and push rods. Main driving force.

Principle: The valve plate of the flip valve automatically opens under the gravity of the material. After the material falls, the counterweight lever system automatically resets the valve plate to prevent wild wind from blowing in, thereby completing the transportation of the material. There are mainly single and double-door flap valves. Double-layer flap valves mainly use the upper and lower valves to switch at different times to keep a layer of valve plate in the middle of the equipment in a closed and partitioned state to prevent air channeling. If it is transported under positive pressure, the pneumatic double-layer air lock valve can also play the role of balance and booster valve to assist the flow, so that the equipment can continuously pulsate the material and have the function of air lock to meet the pneumatic pressure. Requirements for conveying powder and granular materials.

Double layer vertical flap valve

The double-layer vertical flap valve mainly uses the opening and closing of the upper and lower valves at different times to keep a layer of valve plate in the middle of the equipment in a closed and partitioned state to prevent air channeling. If it is transported under positive pressure, the pneumatic double-layer air lock valve can also play the role of balance and booster valve to assist the flow, so that the equipment can continuously pulsate the material and have the function of air lock to meet the pneumatic pressure. Requirements for conveying powder and granular materials.

Double-layer flap valve product features:

★Simple structure and good air tightness;

★ The valve plate and valve seat alternately open and close to maintain high sealing;

★ Wear-resistant, suitable for sealing at high temperatures;

★ It is not easy to cause bridge or jamming;

★ Flanges are available: square and round;

★A variety of materials can be selected according to customer requirements: stainless steel (SS304, SS304L, SS316, SS316L), carbon steel, etc.;

★ Optional driving methods: hammer type, pneumatic and electric