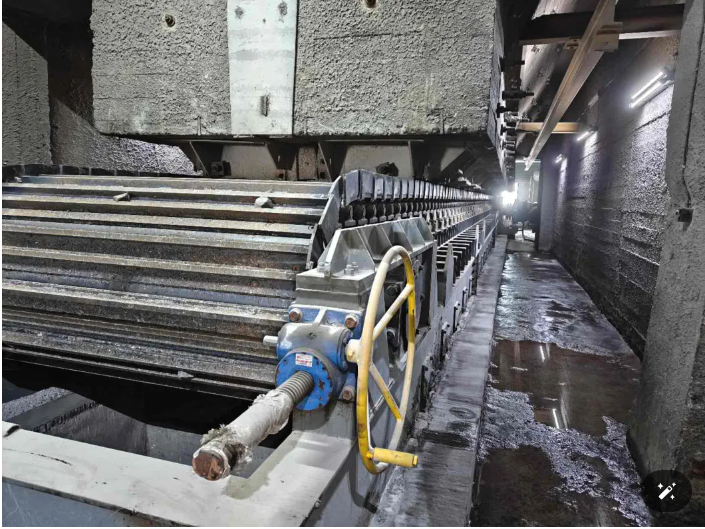

Apron Feeder for Conveying Materials

Apron feeder is one of the machines for continuously transporting materials.It is widely used to transport large-volume materials to various crushing equipments uniformly and continuously in a short distance.LBJ type apron feeder is a newly developed efficient feeder machine of our company,which is based on introducing foreign advanced technology.It can perfectly solve the transportation problem of loose and block materials as well as large feeding quantity problem in large and medium production lines.It is especially suitable for transporting large,high temperature and sharp materials,and it can reliably work in harsh and humid outdoor environments.Now the apron feeder has been widely used in cement,building materials,metallurgy,mining and other industrial sectors for its superior performance advantages.

Technical Specifications

| Model | LBJ-1000×5000 | LBJ-1300×6000 | LBJ-1500×8000 | |

| Max.Feeding Size(mm) | ≤600 | ≤800 | ≤1100 | |

| Capacity (t/h) | 100-500 | 150-750 | 300-1000 | |

| Max. Tilt Angle | 20° | 20° | 20° | |

| Motor (inverter)(kw) | 11-15 | 15-18.5 | 22-37 | |

| Feed Chute. | Plate Width (mm) | 1000 | 1300 | 1500 |

| Plate Thickness(mm) | 20 | 20 | 20 | |

Features

1.Wide application.It can transport materials and goods that have sharp edges.And large materials are available.It is also suitable to convey high temperature materials that are below 400ºC.

2.Flexible layout.The apron feeder can make both left drive and right gear.It can deliver materials horizontally and slantly.Users can choose inclination angle between 0 to 20 degrees according to the actual site.

3.The whole machine adopts self-aligning roller bearings,which has features of small running resistance,easy maintenance and high use efficiency.

4.Good airtight performance.It does not spread and leak materials during running and unloading process.

5.Large carrying capacity.The slot board adopts stamping and welding structure,being able to adapt the delivery of denser materials.

6.Smooth and reliable operation;low noise.

7.Double automatic overload protection function.It reduces the risk of overload failure in production process.

8.Frequency converter and inverter motor can adjust conveying speed.It can better solve the uneven feeding problem in actual production.

9.Long durability;easy maintenan