ABOUT US

Bootec

Bootec

INTRODUCTION

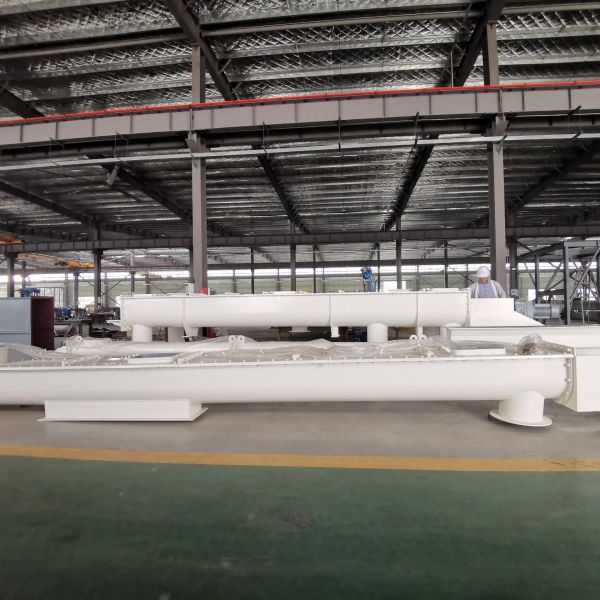

Founded in 2007, Jiangsu Bootec Environment Engineering Co., Ltd. is the leader in the design and manufacture of conveying equipment for the bulk material handling industry. We design and build complete customized conveying systems and solutions, such as scraper conveyors, chain conveyors, screw conveyors, bucket elevators, belt conveyor, chutes, silos, etc. Our process has been proven over thousands of applications in all major bulk material processing industries. BOOTEC is an EN1090 certified metal construction company and an ISO 9001:2015 certified manufacturer. We are committed to customer satisfaction and continuous improvement of our products and services.

-

-2 PRODUCTION PLANTS

-

-OVER 16 YEARS PROFESSIONAL EXPERIENCES

-

-28 AUTHORIZED PATENTS

-

-OVER 200 PROJECTS WORLDWIDE

-

-OVER 5600 INSTALLATIONS WORLDWIDE

Why Choose Us

Bootec

NEWS

Service First

-

Scraper Conveyors for Waste-to-Energy Plants

Scraper Conveyors for Waste-to-Energy Plants Why Choose Us • Specialized Expertise: We focus on conveyor solutions tailored for waste-to-energy (WtE) facilities. • Durability: Built to withstand high temperatures and abrasive ash. • Efficiency: Continuous operation ensures minimal downtime and ma...

-

Industries That Use Scraper Conveyors

Scraper conveyors are mainly needed by heavy industries that handle bulk materials such as mining, cement, steel, power plants, and waste management. Industry Why They Need Scraper Conveyors Mining Transport coal, ore, and other raw minerals through underground tunnels or processing plant...

-

Bootec Awarded Chain Conveyor Contract for European Biomass Plant

Jiangsu Bootec Environment Engineering Co., Ltd. has recently been awarded a contract for the design and supply of three chain conveyors for a biomass power plant in Europe. This project further strengthens Bootec’s presence in the European market and highlights its expertise in providing reliabl...